Services and projects

Rightly you expect - within short time - a solution for your engines, be they planned, in development, or in operation.

Past experience shows that an early involvement of external specialists in the development of engines is a prerequisite to implementing projects appropriately. Together with your engineers we analyse the technical engine requirements and, subsequently, during workshops we refine the whole project according to your objectives.

Furthermore - depending on your order - we provide you with our expertise during the design and development phase.

Upon completion of these project phases the tests of a close-to-production prototype and the motor systems take place. The comprehensive scope of high-tech test procedures on reytex test beds delivers valid results.

reytex delivers measurement results and concrete proposals for action.

Concept

|

|

Conceptual tasks mark the beginning of a project in order to achieve given objectives. The definition of technical requirements is a characteristic of engine construction. Particularly important are also organisational preconditions, which we include in our concept.

The reytex concept consists of a detailed development plan for engine and undercarriage. |

|

| |

Design

|

|

In the design stage the focus is on engine specific requirements with regard to:

- How efficient the potential of the variable engine components will be used, and

- If the desired result will be met in terms of quality and date due.

|

|

| |

Analysis

|

|

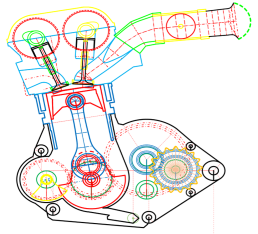

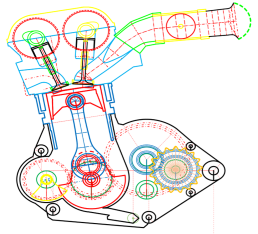

Analysing system and components is another significant part of engine development. Here we focus on performance components, oil and cooling circuit, gear box, and exhaust gas components (exhaust, silencer, and catalytic converter).

In particular we look at the intake system (airbox, carburettor, throttle flap, combustion chamber, and cylinder head) and elaborate an efficient interaction of these components. |

|

| |

Analysis of used components (FMEA)

|

|

Our quality standards next call for the failure mode and effect analysis (FMEA), which allows the identification of potential failures and risks already during development. Corresponding to the quality standards we deal with effect, type, and cause of failures.

We limit ourselves not only to the identification of failures but also develop further actions and solutions with you. |

|

| |

Validation and testing

|

|

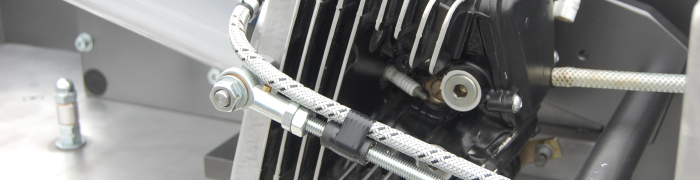

Validation is the core activity in the development of vehicles. Its purpose is to verify, if the system achieves the desired requirements. Validation includes measurements of current, oscillation, and vibration. Individual components (cylinder head, piston, rod), groups of components (valve operation, crank and gearing mechanism, oil and cooling circuit) as well as whole vehicles are being validated. |

| Read more > |

|

| |

Training and on-site workshops

|

|

Training of process and project development are part of our basic services.

reytex on-site training is a direct component in the implementation of individual steps. We compile a technical development plan in order to complete your project on time.

The implementation of projects according to international standards guarantees sustainable success. |

| |

| On-site workshops - customised - strategic. |

|