Validation and Test

Validation is the core activity in the development of vehicles. Its purpose is to verify, if the system achieves the desired requirements. Validation includes measurements of current, oscillation, and vibration. Individual components (cylinder head, piston, rod), groups of components (valve operation, crank and gearing mechanism, oil and cooling circuit) as well as whole vehicles are being validated.

The validation stage is necessary not least because of economic reasons. You can avoid the high cost of possible recalls as well as reduce risks.

Dependent on the units to be examined, real tests on the test bed, simulations, or a combination of both will be performed.

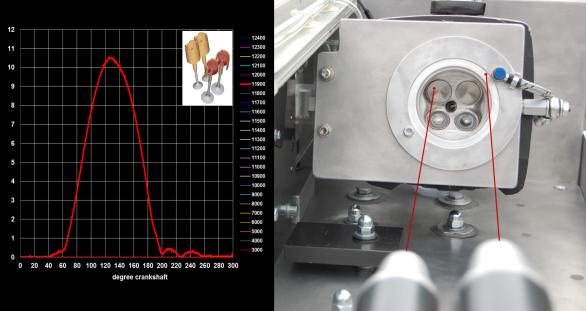

Dynamics / acoustics of valve operation: Measurements at the engine test bed

Maximum performance at optimal fuel consumption. In particular the valve operation of existing or newly developed engines offers consistently potential for improvement.

In the past measurements of the dynamics of valve operation were predominantly used in racing. Nowadays, increasing requirements for engine efficiency request a continuing optimisation of the dynamic properties of valve and control. Already during construction and development of an engine extensive tests of the valve operation are essential.

Only this way cost and time consuming development cycles can be avoided.

The valve operation is measured:

- during the development of a new engine,

- during production, in order to increase the efficiency of an engine.

By use of laser vibrometry or acoustic measurement the valve operation is tested and optimised with regard to kinematics, dynamics and acoustics.

Flow dynamics - intake - exhaust system

We offer dynamic flow measurements as compared to static measurements. Does the engine achieve its full potential at the desired torque and fuel consumption? This has to be exactly determined.

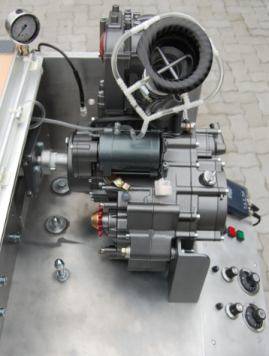

reytex-built test beds offer:

- dynamic flow measurements of intake and exhaust system,

- dynamic measurements of valve operation by use of laser vibrometry,

- acoustic measurements, as well as

- friction loss of engine and subassemblies.

reytex component and system test beds are used by our customers on-site or in our Chinese test centre.